What Does Roof Nuts Do?

Fascination About Roof Nuts

Table of ContentsThe Roof Nuts StatementsRoof Nuts Can Be Fun For EveryoneThe smart Trick of Roof Nuts That Nobody is Talking AboutNot known Factual Statements About Roof Nuts

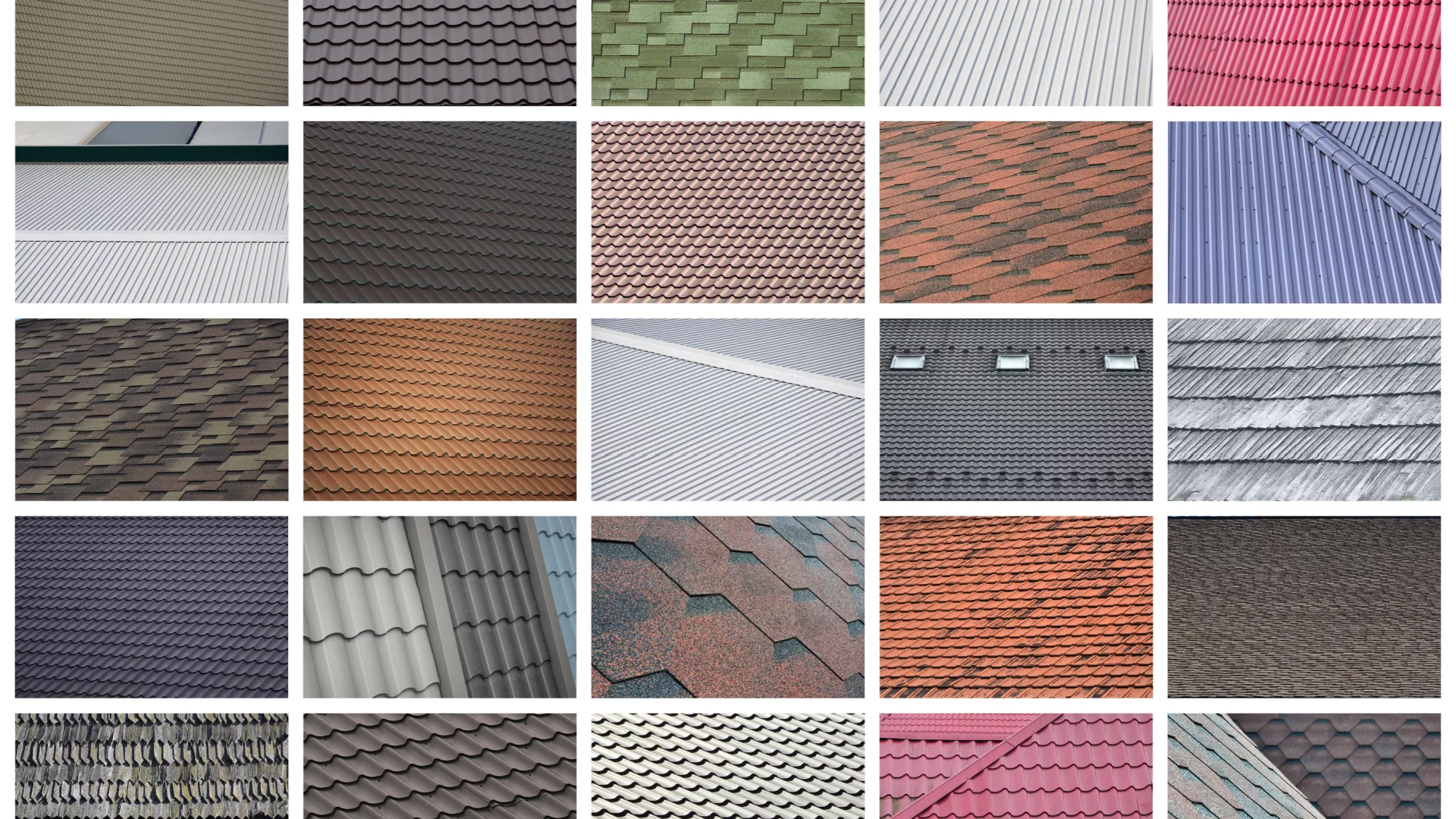

Made from a synthetic polycarbonate layer integrated with strengthening scrim, TPO roof is set up utilizing heat welding, developing a solid and sturdy bond with the roof deck. This approach of installment makes sure that TPO roofs can last as much as 25 years with proper care and maintenance. TPO roof covering product is readily available in various sizes, making it functional for different level roof applications. PVC roof covering is not suggested for steep slopes, as well as locations with heavy snowfall or freeze-thaw cycles. PVC roofing integrates resilience with ease of setup, making it a preferred choice for numerous level roof covering applications.These systems, also described as accumulated roof, are made up of numerous layers of asphalt-impregnated roof covering really felt and asphalt, developing a robust and water tight barrier against the elements. The top layer normally features carefully crushed stone granules, giving a wear-resistant surface area that can stand up to the roughness of time. The systematic application process of BUR warranties correct bond of each layer, therefore enhancing the roofing system's total toughness and durability.

The 9-Second Trick For Roof Nuts

BUR is known for its cost-effectiveness, supplying a competitive cost per year of expected solution life contrasted to other industrial roof systems. With a life expectancy ranging from 15 to thirty years, BUR provides a reliable and resilient roofing remedy for both domestic and commercial buildings. Its ability to manage various weather and its cost-effectiveness make BUR an appealing alternative for numerous home proprietors.

thanks to the addition of unique polymers. This asphalt-based material is customized to boost its versatility and durability, making it appropriate for a large range of climates and applications. Modified bitumen roofing is manufactured into rolls with either smooth or granulated surface areas, providing different alternatives for various roof covering requirements. There are different types of modified asphalt roof covering, with typical polymers such as atactic polypropylene (APP) and styrene butadiene styrene (SBS) used in the cap sheet.

With appropriate installation and upkeep, modified bitumen roof covering can last between 20 and 30 years - https://experiment.com/users/ro0fnutsga. Modified bitumen roofing can be installed using numerous methods, each using its very own benefits. The torch-applied approach entails heating up the bottom of the roofing product with a gas lantern to stick it to the substrate. The cold adhesive method includes applying a specially created glue to the substratum prior to laying down the modified asphalt sheets. There are additionally self-adhesive customized asphalt sheets that come with a pre-applied glue layer, getting rid of the requirement for open fires throughout installment. Each technique has its benefits, yet all require experienced professionals to make certain ideal efficiency and durability

The Best Strategy To Use For Roof Nuts

Steel roof coverings can significantly boost the aesthetic charm of your building, making them a preferred selection for both property and business structures. For level roofing systems, there are largely two types of steel roofs: standing seam and screw-down panel systems. Standing joint metal roofing systems be composed of panels locked with each other at the seams, permitting growth and tightening. Steel roofing provides several benefits, consisting of sturdiness and longevity. Metal flat roofing can last approximately 35 years in optimal problems, making it a dependable long-lasting investment. Furthermore, metal roofing systems can quickly drop snow and ice, avoiding the build-up that can cause damage. However, among the significant drawbacks of steel roof covering is its greater preliminary cost contrasted to other roof covering products.

Liquid roof has a fairly simple application procedure that ensures smooth, efficient insurance coverage. These systems can be put on a selection of surfaces, including metal, BUR, and single-ply membranes. The complying with subsections will discover the various types of fluid finishes and the application process in detail. There are several kinds of liquid finishes made use of in roof covering, each offering unique benefits: Silicone finishes master weather resistance and can withstand ponding water without breaking down.

The Best Guide To Roof Nuts

Initially, the roofing system surface area must be completely cleaned up and fixed to remove any particles, dirt, or damaged locations that can prevent the finish's try this site efficiency. This preparation stage is important as it establishes the foundation for a smooth and resilient roof layer. As soon as the surface area prepares, the fluid coating is usually applied utilizing spray equipment or rollers for even coverage.

The ordinary lifespan of a level roof covering has to do with twenty years, which impacts the overall worth stemmed from the first investment. Labor costs are a considerable component of repair service expenses and can significantly influence the lasting worth of a level roof covering - https://www.domestika.org/en/ro0fnutsga. Purchasing a sturdy and long-lasting roofing product can save cash in the future by reducing the regularity and price of fixings and upkeep